- HOME

- ABOUT US

- Machines & Equipment

- Army Military Products

- Army Military Uniforms

- Army Military Body Armour

- Army Military Shoes

- Army Military Ballistic Helmets

- Army Military Tactical Bulletproof Vest

- Army Military Bulletproof Vest

- Army Military Anti Riot Armour

- Army Military Ballistic Overvest

- Army Military Bomb Blankets

- Army Military Bomb Detection Equipments

- Army Military Bomb Disposal Search Tools

- Army Military Caps and Hats

- Army Military Uniform Accessories

- Army Military Defence and Police Supplies

- Army Military Riot Drill Materials

- Army Military Ceremonial Dress Accessories

- Army Military Tents

- Military Jacket

- Military T-Shirt

- Military Combat Suits

- Military Raincoat

- Military Pants

- Military Cap

- Military Garment

- Military Backpack

- Army Cap and Beret

- Military Belt

- Army Stretcher

- Military Mask

- Military and Police Equipment

- Food Processing Equipments

- Tomato Processing Plants

- Fruit Juice Processing Plants

- Fruit Processing Pulp and Jam Plant

- Dairy Processing Plant and Machinery

- Vegetable Processing Plant

- Food Processing Line Machines

- Meat Processing Machines

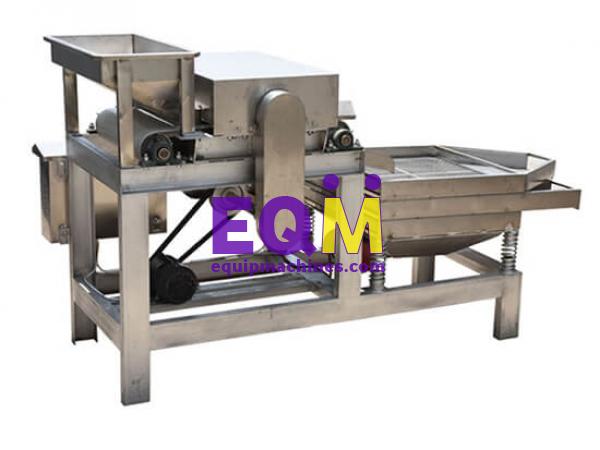

- Nuts Processing Machine

- Food Packing Machine

- Snacks Making Machine

- Milk Processing Equipments

- Refrigeration and Cold Storage Machines

- Tea Bag Machine

- Potato Processing Machines

- Vegetable and Fruit Equipment

- Juice Machinery

- Other Food Machinery

- Pasta Processing Machines

- Ice Cream Machines

- Can Filling Machine

- Relief and Aid Products

- Hand Tools and Machines

- Solar Energy Plant and Equipments

- 3D Machine and Equipments

- Agricultural Machinery and Equipments

- Tractors Equipment

- Tillage Implements Equipment

- Sowing Equipment

- Weeding and Intercultural Equipment

- Plant Protection Equipment

- Harvesting Equipment and Combine Harvesters

- Threshers Reaper and Binders Equipment

- Crop/Grain/seeds Cleaning, Grading and Weighing Equipment

- Maize Shelling and Grinding Equipment

- Sowing and Planting Equipment

- Pesticides Sprayers

- Drilling and Bore Well Equipments

- Water Irrigation Equipments

- Agro Processing Equipments

- Water Treatment Solutions

- Fire Detection Equipments

- Fire Fighting Equipments

- Construction Machinery And Equipments

- Excavator

- Bulldozer

- Wheel Loader

- Backhoe Loader

- Motor Grader

- Road Roller

- Multi-Function Asphalt Paver

- Crane

- Mining Dump Truck

- Concrete Pump Truck

- Forklift Truck

- Fire Fighting Trucks

- Municipal and Special Vehicle

- Geotechnical Machines

- Industrial Pump

- Road Milling Machine

- Drilling Rig Equipments

- Concrete Mixer Truck

- Ground and Underground Engineering Equipments

- Food Processing Equipment and Machines

- Aseptic Carton Filling Machine

- Filling and Packaging Machine

- Stainless Steel Tanks

- Preparation System

- Sterilization System

- CIP Cleaning System

- Carbonated Beverage Equipment

- Drinking Water Treatment Equipments

- Sanitary Pumps

- Installation Pipelines, Valves, Fittings

- Utilities Equipment

- Labeling and Packing Machines

- Strapping and Sealing Machine

- Bottle Filling and Batch Coding Machinery

- Fruit Processing Equipment

- Processing Plant

- Automobile and Garage Tools

- Power and Electrical Equipment

- Water Treatment Plants

- Packing Machines and Equipment

- Auxiliary Equipment

- VFFS Machines

- Pillow Type Packing Machines

- Cup Fill Seal Machines

- Aluminum Foil EPE Sealing Machines

- Vacuum Packaging Machine

- Packing Machines

- Tobacco Packing Machines

- Line Carton Packing Machine

- Horizontal Flow Wrap Machines

- Multi-track And Stick Pack Packing Machines

- Collar Type Packing Machines

- Fully Pneumatic Machines

- Premade Pouch Packing Machines

- Premade Pouch Packaging Line

- Safety and Security Equipment

- Battery Operated Transport Vehicle

- Army Military Products

- Blogs

- Contact